Dyneema® Bio-circular Fibre

Ejendals was the first personal protective equipment (PPE) supplier in Europe to introduce cut-resistant gloves made with bio-attributed ultra-high molecular weight polyethylene (UHMWPE) fibres – also known as high-performance polyethylene (HPPE).

We have developed the first gloves that combine exceptional cut resistance with sustainability, using Avient’s Dyneema ® bio-circular UHMWPE fibres.

The production of these bio-attributed fibres follows the ISCC-certified mass balance approach, which ensures traceability and accountability of the renewable content along the Chain of Custody. The renewable feedstock for the manufacturing of Dyneema ® bio-circular fibre originates from waste streams of the pulp and paper industry. Both renewable and fossil feedstocks are combined in the process to produce ethylene. The renewable share is then attributed to selected products. All production steps use existing infrastructure and processes, and switching from conventional to Dyneema ® bio-circular fibres means no change in product performance.

Thanks to the Diamond technology, the cut resistance of Dyneema ® fibre more than doubles when compared to conventional HPPE fibres. This unique polymer provides ultra-thin cut resistant material, high strength, high abrasion and superior fingertip sensitivity and cool-touch comfort.

Environmental benefits:

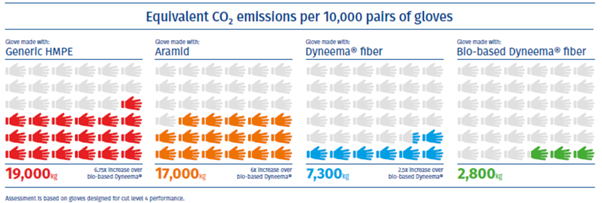

• Switching to Dyneema ® bio-circular fibres can reduce the carbon footprint of glove production by up to 90% compared to conventional fossil-based Dyneema ® fibers.

• Each pair of gloves made with these fibres saves approximately 0.45 kg CO2 eq.

• Certified by the International Sustainability & Carbon Certification (ISCC), this Dyneema ® bio-circular fibre supports sustainability initiatives without sacrificing safety and comfort.

CARBON DIOXIDE FOOTPRINT COMPARISON

|

Aramid |

Dyneema ® |

Dyneema ® bio-circular fibres |

|

1.7 kg CO2 eq |

0.73 kg CO2 eq |

0.28 kg CO2 eq |

|

6x increase compared to Dyneema ® bio-circular |

2.5x increase compared to Dyneema ® bio-circular |

|

The table shows an example of how much carbon dioxide is emitted for the production of 1 pair of gloves made with the mentioned fibres. Source: Avient.